1. What Are Suspension Clamps

A suspension clamp is an ab cable accessory used to fix and suspend overhead line conductors. It can fix the conductors on the insulator string or suspend the lightning protection line on the straight pole tower. It can also be used to support the transposed conductors on the transposed pole tower and fix the jumper of the tension angle pole tower. It is mainly composed of the wire clamp body, pressure plate, bolts, and other parts. The wire clamp body is usually made of metal materials with certain strength and corrosion resistance, such as aluminum alloy, galvanized steel, etc.

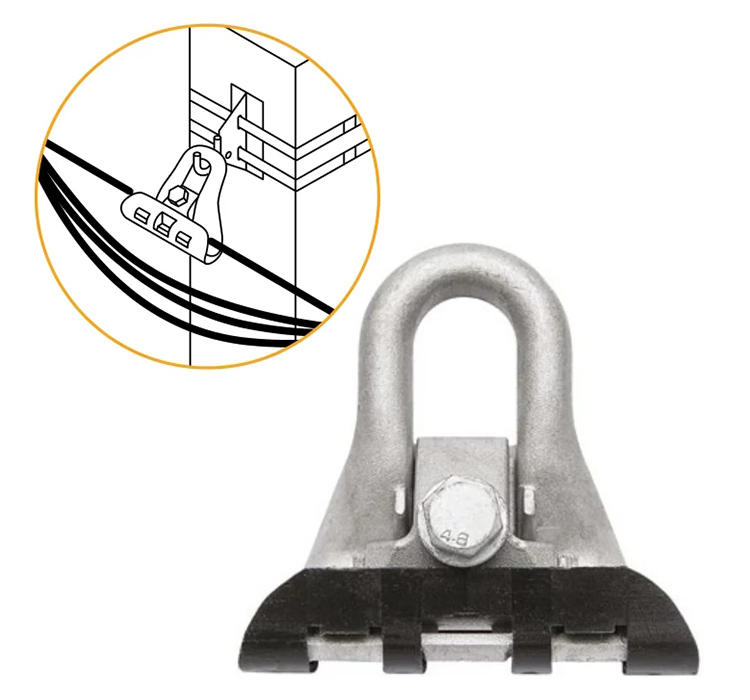

SJ94 series suspension clamps Application

2. How Do Suspension Clamps Work

The working principle of aerial cable suspension clamps mainly relies on the friction between the wire and the metal clamp, and the pressure applied to the overhead wire by the metal pressure plate. When the wire passes through the aerial cable suspension clamps, a certain amount of pressure is applied to the wire through the suspension clamp’s pressure plate and the tightening of the bolts, so that sufficient friction is generated between the wire and the clamp. This friction can overcome the wire’s deadweight and the wire’s tension, thereby ensuring that the wire can be firmly fixed in the air. And the use of straight cable suspension clamps can allow the overhead wires to have a certain droop angle, so that they can swing within a certain range, thereby relieving the tension of the wire to cope with bad weather.

3. Material of Overhead Line Suspension Clamp

The material of the suspension clamp will directly affect its performance. The main materials currently used are aluminum and the following:

Aluminum alloy suspension clamp: Aluminum alloy is the most commonly used material for tension clamps for overhead lines. They are light in weight, have strong corrosion resistance, and are suitable for harsh environments.

Galvanized steel suspension clamp: Galvanized steel has high strength and relatively low cost, and is suitable for occasions with severe weather such as wind speed or snow and ice cover.

Stainless steel suspension clamp: Stainless steel has extremely high corrosion resistance, which can ensure long-term use in corrosive environments, such as coastal areas, chemical plants, and other scenes.

Composite materials: Composite materials are generally suitable for overhead lines with special requirements, such as insulated suspension clamps. They have unique properties, such as high strength, low expansion coefficient, good insulation, vibration-damping effect, etc.

4. Advantages of Suspension Clamps for Overhead Lines

Suspension clamps have many advantages, but they are widely used in overhead lines mainly due to the following advantages:

4.1 Improving the stability of overhead lines

The suspension clamp can stably fix the overhead cables through friction and pressure and can bend and rotate, automatically adjusting the angle to reduce the damage of the wires due to gravity and external forces, especially in severe weather such as ice, snow, and strong winds. This is particularly important. Therefore, the suspension clamp for ABC cable can effectively enhance the safety and stability of overhead lines.

4.2 Strong adaptability

Aerial cable suspension clamps are made of high-strength materials such as stainless steel, aluminum alloy, galvanized steel, etc. as AB cable accessories. They have good physical and chemical properties, so they can adapt to different weather and usage scenarios. Whether it is in coastal high-corrosion areas or harsh environments such as strong winds and blizzards, suspension clamps for ABC cables are a good choice.

4.3 Good durability

The structural design of the suspension clamp is simple and made of durable raw materials, which also leads to good durability. The ABC suspension clamps produced by SUNJ will undergo rigorous testing before leaving the factory, including tensile strength testing and durability testing, to ensure that they can be used for a long time under various environmental conditions without damage.

4.4 Easy to install and maintain

The installation position of the suspension clamp is relatively high, generally installed on the cross-arm or corner of the overhead wire, so their installation and maintenance must be simple, which is one of the main reasons why they are widely used in overhead lines.

5. Why Overhead Lines Need Suspension Clamps

After reading this, you may be confused as to why we must use suspension clamps instead of other devices or directly suspending overhead wires. The use of suspension clamps not only improves the safety of the entire overhead power system but also reduces the pressure on the poles. As long-distance transmission puts a lot of pressure on each pole, if the pole is unevenly loaded, it will become unstable and this will affect the stability of the overhead lines. The last point is what was mentioned earlier. The application of suspension clamps allows the overhead cables to have a certain swing range, which can cope with all kinds of bad weather.

Therefore, if aerial cable suspension clamps are not used, the overhead lines may need frequent maintenance, and the transportation of electricity will not be stable, which will increase the operating costs.

6. Applications of Suspension Clamps for Overhead Line

Overhead transmission lines: Suspension Clamps are used to firmly suspend the wires on the pole towers to ensure the transmission of electricity.

Communication lines: Suspension Clamps can be used to fix communication optical cables to ensure the stable transmission of communication signals.

Railway electrification lines: double suspension clamps are used to suspend contact wires to ensure a stable and reliable power supply for trains.

Special high-altitude wiring scenarios: such as lines crossing canyons and rivers, Suspension Clamps play a key role, enabling the lines to safely cross these special terrains.

Overhead lines in the field of new energy: such as wind power generation and suspension Clamps are also important components to ensure the normal operation of the line.

suspension clamp Application

7. Installation of Suspension Clamps in Overhead Lines

Installation of Suspension Clamps in overhead lines requires strict installation steps:

Determine the installation location: First, determine the location of the suspension clamp on the steel pipe or wire according to the needs of the power line. The general installation location should be more than 1200mm from the ground.

Installation bolts: After determining the installation location, we need to drill holes in the wires or steel pipes, insert the bolts into the holes, and fix the other end with nuts and washers.

Fix the suspension clamp: Slowly put the suspension clamp on the bolt and fix it with pliers.

Check the fixing: After confirming that the suspension clamp is firmly fixed, not loose, and without any tilt, the installation operation can be completed.

8. FAQS

Q: Does the suspension clamp need frequent maintenance?

A: Generally speaking, if the suspension clamp is not in a very harsh environment, we do not need to check and maintain it frequently, but we still need to check it regularly to check the wear and stability of the suspension clamp.

Q: How to choose the right suspension clamp for your project?

A: First, you need to determine the material to be used based on the application scenario. For example, for high-voltage overhead transmission lines, select a clamp that can withstand high mechanical tension and conductor weight. Then, select the clamp model based on the conductor diameter and material of the overhead line. Finally, consider factors such as load-bearing capacity, installation, and cost. Through a comprehensive judgment of these key factors, you can choose the aerial cable suspension clamps that are suitable for you.

Q: What is the service life of the suspension clamp?

A: The service life of aerial cable suspension clamps is closely related to their materials, usage environment, etc. For example, aluminum alloy suspension clamps can have a service life of up to 20 years if properly maintained, and stainless steel suspension clamps can have a service life of up to 25 years.

9. Conclusion

Although overhead line suspension clamps are very small and inconspicuous cable accessories, they are crucial to ensuring the stability and safety of overhead wires. Whether it is a high-voltage power transmission line or an ordinary low-voltage overhead transmission line, suspension clamps play a vital role in keeping the conductors stable and operating safely.

So, the next time you look up and see those overhead power lines, remember that it is the suspension clamps that are silently ensuring everything is stable for us.