What is a Suspension Clamp?

A suspension clamp is a vital component used to secure and support overhead conductors on utility poles or towers. Commonly found in overhead transmission lines, it acts as a mechanical link between the cable and the supporting structure—ensuring the wire stays suspended, stable, and safe under varying loads.

In real-world power line projects, suspension clamps serve the following functions:

- Fix the conductor onto insulator strings or cross-arms;

- Support lightning protection wires on straight pole towers;

- Hold jumpers or transposition conductors on angle or transposed structures;

- Allow limited swing or rotation, helping the cable withstand environmental stress like wind, ice, or thermal expansion.

Each suspension clamp typically consists of a metal body, pressure plate, bolts, and sometimes washers—all made from high-strength, corrosion-resistant materials such as aluminum alloy, galvanized steel, or stainless steel.

Think of it like the “seatbelt” for your overhead wire—securing it in place while allowing just enough flexibility to absorb the shocks from nature.

ES54-14 Suspension Clamp With Bracket Application

How Do Suspension Clamps Work?

Suspension clamps function through a combination of mechanical clamping force and friction, designed to securely hold overhead conductors in place while allowing limited movement under external stress.

Suspension Clamp for Overhead Lines

Here’s how they work in practice:

Clamping Pressure

When installed, the suspension clamp applies pressure to the conductor using a metal pressure plate, which is tightened via bolts and nuts. This clamping action ensures:

- Stable positioning of the conductor,

- Firm contact without damaging the cable sheath,

- Reliable operation even under varying loads.

Friction-Based Fixation

The friction between the conductor and the clamp body is critical. Once sufficient clamping pressure is applied, the frictional resistance is strong enough to counteract the weight and tension of the cable, keeping it securely suspended—even over long spans.

Dynamic Movement & Tension Relief

Unlike rigid clamps, suspension clamps allow a controlled swing angle—a slight downward droop and horizontal swing. This flexibility reduces mechanical stress during:

- Strong winds

- Ice or snow accumulation

- Thermal expansion or contraction

This capability makes them ideal for overhead cable systems in harsh or shifting environments, such as mountainous regions, coastal zones, or high-altitude towers.

Expert Insight:

In real engineering projects, the suspension clamp not only “holds” the wire—it plays a protective role by dispersing stress loads and preventing mechanical fatigue in the conductor over time.

Parts & Materials of a Suspension Clamp

A suspension clamp may seem like a small accessory, but it plays a crucial role in the mechanical support system of overhead lines. To better understand how it works and why it performs the way it does, it’s important to look at both its core components and the materials used to manufacture them.

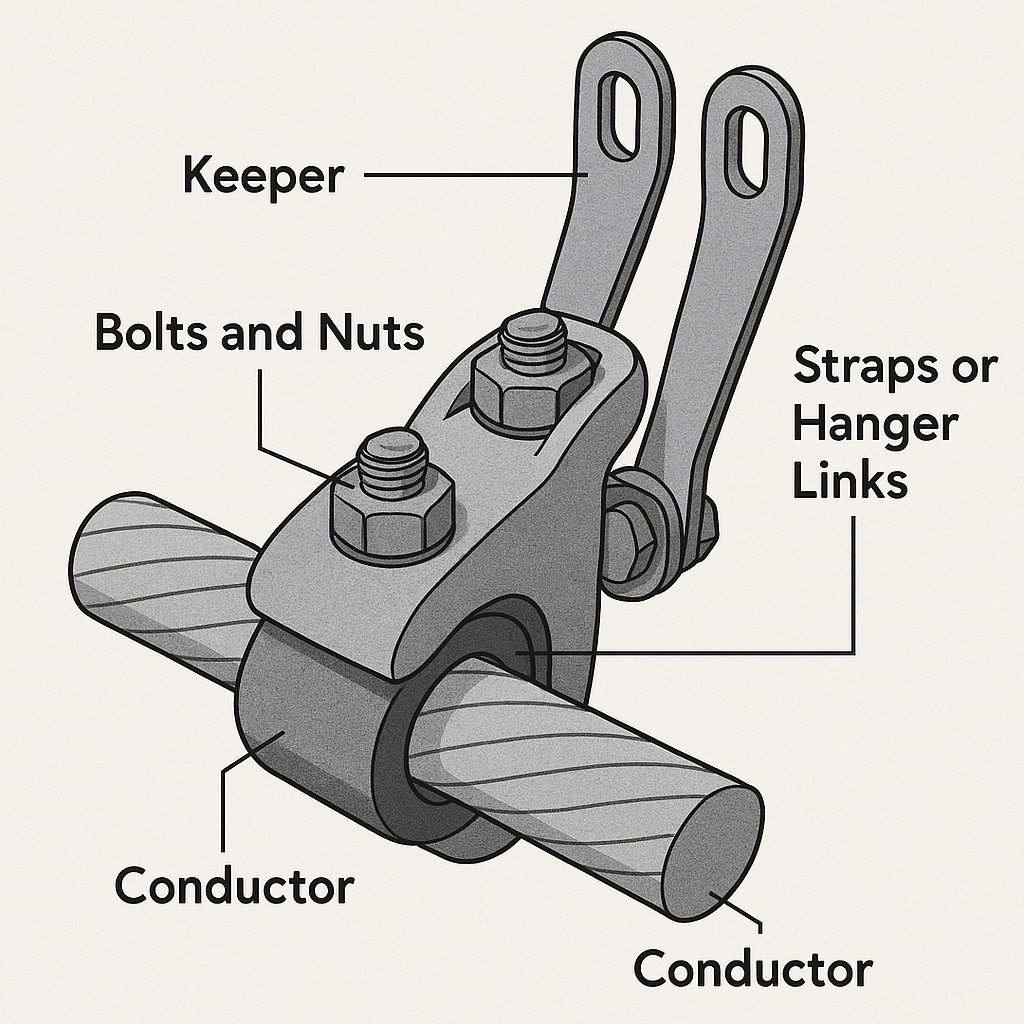

3.1 Main Components of a Suspension Clamp

Most overhead line suspension clamps are made up of the following key parts:

Clamp Body (Frame):

This is the main load-bearing structure of the clamp, responsible for enclosing and supporting the conductor. It is usually made from high-strength metal alloys to ensure durability under mechanical stress.

Keeper (or Pressure Plate):

The keeper holds the conductor tightly against the clamp body. It applies pressure evenly across the cable and is essential for maintaining a firm grip without damaging the conductor surface.

Straps or Hanger Links:

These are used to connect the clamp to the insulator string or the pole cross-arm. They transfer the mechanical load from the clamp to the support structure.

Bolts and Nuts:

High-tensile steel fasteners are used to secure all parts together. These bolts are responsible for applying the correct clamping force and are designed to withstand long-term tension and vibration.

Washers:

Washers provide additional stability and ensure that the bolts distribute pressure evenly, especially when the surface isn’t perfectly aligned.

3.2 Materials Used in Suspension Clamps

The performance and longevity of a suspension clamp depend heavily on the materials used in its construction. Below are the most common materials and their key properties:

Aluminum Alloy:

Lightweight, corrosion-resistant, and suitable for coastal or humid environments. Commonly used in high-voltage transmission systems due to its excellent conductivity and low maintenance.

Galvanized Steel:

Known for its high tensile strength and lower cost. The zinc coating protects the base steel from rust, making it ideal for areas with heavy wind or ice loads.

Stainless Steel:

Offers exceptional corrosion resistance in extreme environments like coastal zones, chemical plants, or industrial areas. It also maintains structural integrity over long service life spans.

Composite Materials:

Used in advanced or insulated applications, especially where electrical isolation or vibration damping is needed. These materials are lightweight, weather-resistant, and electrically non-conductive.

Expert Insight

The right combination of parts and materials not only affects the clamp’s ability to hold the conductor but also determines how well it resists corrosion, adapts to environmental stress, and ensures the safety of the overhead line system.

Types & Advantages of Suspension Clamps for Overhead Lines

Suspension clamps come in various types to meet the specific needs of different overhead line systems, from low-voltage ABC cables to high-voltage OPGW setups. Each clamp type is designed with certain environments, conductor types, and mechanical requirements in mind.

Below is a breakdown of the most common types of suspension clamps, along with their advantages and ideal application scenarios.

4.1 Suspension Clamp for ABC Cable

These are specially designed for aerial bundled conductors (ABC), often used in urban or suburban power distribution networks.

Key Benefits:

- High corrosion resistance for outdoor use

- Strong grip on insulated cables

- Easy installation on poles and walls

- Prevents conductor sag under heavy loads

Best for: Low-voltage distribution lines in residential areas.

4.2 ADSS Suspension Clamp

Designed for All-Dielectric Self-Supporting (ADSS) fiber optic cables, these clamps ensure no metallic contact with the cable, maintaining insulation integrity.

Key Benefits:

- Electrical insulation to prevent arcing

- Lightweight but strong composite structure

- Weather and UV resistant

- Maintains cable bending radius

Best for: Fiber optic communication lines across rural or high-voltage environments.

4.3 OPGW Suspension Clamp

Used in Optical Ground Wire (OPGW) systems, these clamps combine power and data transmission within a single cable.

Key Benefits:

- High tensile strength

- Secure vibration control

- Maintains conductor optical performance

- Effective for long-span overhead routes

Best for: High-voltage transmission towers requiring communication capability.

4.4 Preformed Suspension Clamp

Also known as helical clamps, these are custom-wrapped fittings that grip conductors along a wider area, reducing concentrated stress.

Key Benefits:

- Minimizes conductor wear and fatigue

- No sharp pressure points

- Easy to install without tools

- Aesthetic and low-profile design

Best for: Aesthetic-sensitive projects or areas prone to high vibration.

4.5 Double Suspension Clamp

Double suspension clamps are designed to handle extra mechanical loads, especially in extreme weather conditions or long-span lines.

Key Benefits:

- Enhanced load distribution

- Improved swing control under high wind

- Suitable for river crossings or mountainous regions

Best for: Harsh terrain applications and long overhead spans.

4.6 U-Type Cable Suspension Clamp

These clamps have a U-shaped body, offering strong support for insulated or bare conductors, often used in mid-span installations.

Key Benefits:

- Simple structure, robust build

- Low-cost and easy to replace

- Widely used in both power and telecom lines

Best for: General-purpose overhead cable support.

4.7 General Advantages of Suspension Clamps

Regardless of type, all well-designed suspension clamps offer the following benefits to overhead systems:

Improved Line Stability

Securely holds the conductor, reducing the risk of sag, breakage, or mechanical fatigue.

Strong Environmental Adaptability

Made from aluminum alloy, galvanized steel, stainless steel, or composites, they perform reliably in wind, rain, snow, and coastal conditions.

Durability & Long Service Life

SUNJ’s suspension clamps undergo rigorous tensile and fatigue testing to ensure years of safe use.

Quick Installation & Easy Maintenance

Most designs use simple bolt-fastening methods, making them easy to install at height with basic tools.

Flexibility in Movement

Suspension clamps allow a controlled swing angle and droop, reducing mechanical stress on poles and conductors.

Expert Tip

When selecting a suspension clamp, don’t just consider the conductor type—evaluate the mechanical load, span length, environmental exposure, and vibration levels to make the best decision.

Why Overhead Lines Need Suspension Clamps

You might wonder: why not just hang conductors directly on poles or towers? Why are suspension clamps considered a “must-have” in every overhead transmission line project?

The answer lies in safety, performance, and cost-efficiency.

1.Even Load Distribution Across Poles

In overhead power lines, mechanical load must be evenly spread across every supporting tower or pole. If a conductor is fastened without proper clamps, the load becomes uneven—putting some poles under excessive strain and causing structural instability.

Suspension clamps help by:

- Supporting the conductor’s weight across multiple points

- Reducing axial tension and lateral swing

- Preventing pole leaning or collapse due to uneven force

2.Protection Against Environmental Stress

Overhead lines face constant exposure to wind, rain, snow, and ice. Without proper suspension:

- Conductors may swing uncontrollably in high winds

- Accumulated ice increases tension and risk of snapping

- Thermal expansion could cause dangerous sagging

Suspension clamps act like shock absorbers, offering controlled flexibility while maintaining firm support. Their ability to allow limited swing and droop helps absorb external forces and prevents damage to both the conductor and supporting structure.

3.Reduced Maintenance & Longer System Life

Using high-quality suspension clamps significantly reduces the frequency of inspections and repairs. They:

- Keep conductors stable over time

- Protect the cable sheath from wear

- Minimise line sag and stress-related failures

This leads to lower operational costs and longer asset lifespan—especially critical in remote or hard-to-access regions.

4.Enhanced Safety for Electrical Systems

A properly suspended conductor is less likely to contact other objects or cross into restricted clearance zones. This improves:

- Public safety (especially in urban or roadside installations)

- Electrical system integrity (reducing short-circuit risk)

- Compliance with safety codes and utility standards

5.Designed for Modern Power Needs

Today’s power lines aren’t just about delivering electricity—they also support communication cables (like ADSS and OPGW), smart grid sensors, and more. These components require:

- Stable physical support

- Vibration protection

- Long-term positioning accuracy

Suspension clamps provide the precision support these modern systems demand.

Real-World Applications of Suspension Clamps in Power & Communication Lines

Suspension clamps are not one-size-fits-all—they’re designed for specific cable types, terrain conditions, and environmental challenges. In real transmission line projects, choosing the right type of suspension clamp can make the difference between system stability and costly failure.

Here’s how they are applied across industries:

suspension clamp Application

1.Overhead Transmission Lines

Suspension clamps are essential in high-voltage transmission line systems, where long spans and high mechanical tension require strong, reliable fittings.

Solutions like tension clamps for overhead lines and straight cable suspension clamps are commonly used to support bare conductors while allowing for thermal expansion and wind-induced movement.

Use Case: National Grid projects across Southeast Asia deploying 110kV and 220kV long-span lines in mountainous terrain.

2.ABC Cable Distribution Networks

In residential and urban areas, suspension clamps for ABC cable (Aerial Bundled Cable) are used to secure insulated conductors to poles or walls. These clamps ensure safe routing of power without conductor damage.

Use Case: Low-voltage smart grid projects in India and Africa, where suspension wire clamps and figure 8 corner suspension clamps are installed to handle tight turns and pole transitions.

3.Fiber Optic Communication Systems

For fiber optic networks, particularly ADSS (All-Dielectric Self-Supporting) and OPGW (Optical Ground Wire) cables, suspension clamps for fiber optic cable provide vibration resistance, insulation, and precise bend control.

Use Case: Railway communication upgrades in Europe using suspension clamp with I hook design for easy mounting on concrete or steel poles.

4.Renewable Energy Infrastructure

In wind and solar farms, suspension clamps are exposed to high wind loads, salt spray, and UV radiation. Galvanized or stainless steel clamps are preferred due to their durability and corrosion resistance.

Use Case: Offshore wind farm grid connections in Northern China using custom suspension clamp in transmission line solutions with dual insulation and anti-slip features.

5.Special Terrain Crossings

When overhead lines cross rivers, ravines, or highways, they require double suspension clamps or reinforced designs to support heavy cable loads over long spans. In sharp-angled structures, figure 8 corner suspension clamps help maintain safe tension and sag control.

Use Case: 500kV transmission river crossing project using a hybrid setup of tension + suspension clamp combinations for structural balance.

6.Supplier-Based Engineering Support

More EPCs and utility companies are turning to suspension clamp suppliers in China due to their cost-effective manufacturing, fast lead times, and ability to offer customised solutions like preformed suspension wire clamps or high-load clamps with smart monitoring capability.

Use Case: Multinational transmission operators sourcing from trusted Chinese manufacturers for both power and telecom projects in Latin America.

How to Install Suspension Clamps in Overhead Lines

Proper installation of suspension clamps in transmission lines is essential to ensure safe, long-term performance of the conductor system. Whether you’re using a suspension clamp for ABC cable, a suspension wire clamp, or a suspension clamp with I hook, following a precise installation process is critical.

Below is a practical step-by-step guide based on real-world engineering experience:

Step 1: Determine the Installation Location

Identify the exact point on the steel pole, cross-arm, or wire where the clamp needs to be installed, based on mechanical and structural needs of the overhead system.

The typical installation height should be no less than 1200mm above ground level.

For corner or angle installations, use a figure 8 corner suspension clamp to allow proper tension transition.

Step 2: Install the Bolts

Once the position is confirmed:

Drill mounting holes in the steel pipe or cross-arm (if necessary).

Insert the high-strength bolts through the holes.

Secure the bolts using washers and nuts, ensuring even torque application.

Step 3: Attach the Suspension Clamp

Place the suspension clamp body over the mounted bolts.

Use tools like pliers or wrenches to gradually tighten the clamp, ensuring the conductor is held firmly but not crushed.

If installing a straight cable suspension clamp, align the conductor centrally in the groove before final tightening.

Step 4: Check the Fixing & Safety

Before completing the operation:

Ensure the clamp is firmly fixed, with no looseness, tilt, or rotational movement.

Visually inspect all bolt connections and confirm there’s no slippage or misalignment.

In sensitive environments like fiber optic lines, confirm the suspension clamp for fiber optic cable maintains proper bend radius and insulation integrity.

A properly installed suspension clamp helps distribute mechanical stress, reduces conductor sag, and increases the overall stability of the overhead line.

How to Choose the Right Suspension Clamp?

With multiple models on the market—each suited for specific conductor types and load conditions—choosing the right suspension clamp for overhead lines requires technical consideration.

Here’s how professionals typically evaluate options:

1.Match the Clamp to the Conductor

- For ABC cable systems: Choose clamps with insulated grooves and anti-slip pads.

- For bare copper/aluminum conductors: Use straight cable suspension clamps or preformed wire clamps.

- For fiber optics (ADSS/OPGW): Look for suspension clamp for fiber optic cable with dielectric properties.

2.Consider the Installation Environment

- Coastal or high-humidity zones: Go with stainless steel or aluminum alloy clamps.

- High-vibration areas (railways, bridges): Use clamps with shock-absorbing features.

- Sharp-angle or turning points: Opt for figure 8 corner suspension clamps.

- High-tension zones: Combine with tension clamps for overhead lines.

3.Assess the Mechanical Requirements

- Verify clamp load capacity against span length and cable tension.

- Check thermal expansion tolerance for long-span, high-voltage lines.

4.Source from Reliable Manufacturers

If you’re sourcing internationally, look for a suspension clamp supplier in China with:

- ISO / CE certifications

- Customisation capability (for composite or insulated lines)

- Proven experience in transmission line projects across industries

A good supplier won’t just sell clamps—they’ll help you engineer the right solution.

Final Thought: Why Suspension Clamps Are Essential to Overhead Line Success

Whether you’re building a low-voltage distribution system or managing a high-voltage transmission corridor, suspension clamps are not optional—they’re fundamental to your system’s performance, longevity, and safety.

They’re engineered to:

- Stabilise conductors against gravity and environmental stress

- Distribute load evenly across poles and towers

- Minimise vibration and fatigue over long spans

- Reduce maintenance costs by preventing premature failure

From suspension wire clamps in residential grids to tension clamp + suspension clamp combos in mountain crossings, the right choice makes a measurable difference.

If you’re looking for expert guidance or competitive solutions, working with a suspension clamp supplier in China like SUNJ ensures both technical support and supply reliability.

Your overhead system is only as strong as its smallest component—choose suspension clamps wisely.