Polymer Insulator

1. Excellent insulation performance, high efficiency and isolation of current, preventing leakage and short circuit, and improving the safety of electricity.

2. High chemical stability, certain resistance to corrosive substances such as acid and alkali, not easy to be corroded and damaged.

3. Easy installation and maintenance, relatively simple structure, convenient installation and replacement.

4. Widely applicable, can be applied to transmission lines of different voltage levels and types.

5. Reduce corona phenomenon, help reduce the probability of corona discharge, reduce energy loss and electromagnetic interference.

6. Beautify the environment, neatly and orderly arranged on the tower, to a certain extent, play a role in beautifying the surrounding environment of power facilities.

7. Overseas Warehouse in Turkey: Fast Delivery, Lower Shipping Costs and Localized Service

Main Products

Dead End Insulator

Dead end insulators are essential components used in power transmissio...

Pin Insulator

Pin insulators are vital components in overhead power transmission and...

Classification Methods and Considerations for Composite Insulators

There are many classification methods of composite insulators, and the following are some common classification methods:

● According to the purpose: including line composite insulators, power station composite insulators, electrical composite insulators, etc.

● According to the structure: It can be divided into rod-shaped suspension composite insulators, pin-type composite insulators, cross-arm composite insulators, pillar composite insulators, wind-deflection-resistant composite insulators, etc.

● According to the type of core rod: It can be divided into acid-resistant core rod composite insulators and non-acid-resistant core rod composite insulators.

Different types of composite insulators may have differences in performance and application scenarios. The specific choice should be determined according to the actual needs and usage conditions. At the same time, when using composite insulators, attention should also be paid to aspects such as its quality and installation and maintenance to ensure its safe and reliable operation.

About SUNJ Polymer Insulator applications

Polymer Insulator means polymer insulator or composite insulator, and its applications mainly include the following aspects:

In the overhead transmission line, it can guarantee the stable transmission of electric power, has good pollution flashover resistance performance, and can adapt to various harsh environments.

In the substation, it is used for the insulation support between devices.

In the electrified railway system, it ensures the reliable insulation between the catenary and other parts.

In some special industrial environments, such as chemical industry, mines, etc., it is applied due to its corrosion resistance and anti-aging performance.

In the new energy fields such as wind power generation and solar power generation, it provides insulation protection for relevant devices.

Over 18 Years Direct Factory

80+

Countries served

32+

Utility Approvals

800+

Projects Executed Globally

SUNJ Products More Information

SUNJ Electric is a power transmission and distribution enterprise with R&D, manufacturing, trading and services. With excellent quality, design and manufacture and competitive prices, SUNJ products are top sellers in China and have exported to Asia, Europe, America, Middle-East and Africa and numberous other regions. We warmly welcome all over the world friends cooperate with us. Together to contribute a better and stronger power system.

Installation considerations for polymer insulators

The following are some precautions for the installation of “Polymer Insulator” (polymer insulator or composite insulator):

1. Clean the surface: Ensure that the installation part is clean and free of oil stains and impurities to ensure good adhesion and contact.

2. Check the insulator status: Carefully check before installation whether there are damages, cracks and other defects on the insulator.

3. Correct installation direction: Ensure that the insulator installation direction is correct according to the design requirements to avoid reverse installation affecting performance.

4. Moderate fastening force: The force of fastening bolts and other connecting parts during installation should be moderate, not too tight or too loose to prevent damage to the insulator or affect the connection reliability.

5. Avoid collision: Operate carefully during the installation process to avoid violent collision with other objects resulting in damage to the insulator.

6. Environmental conditions: Try to install under appropriate environmental temperature and humidity to avoid adverse effects of extreme conditions on the installation quality.

7. Follow the installation specifications: Operate strictly in accordance with relevant installation specifications and standards to ensure that the installation quality meets the requirements.t.

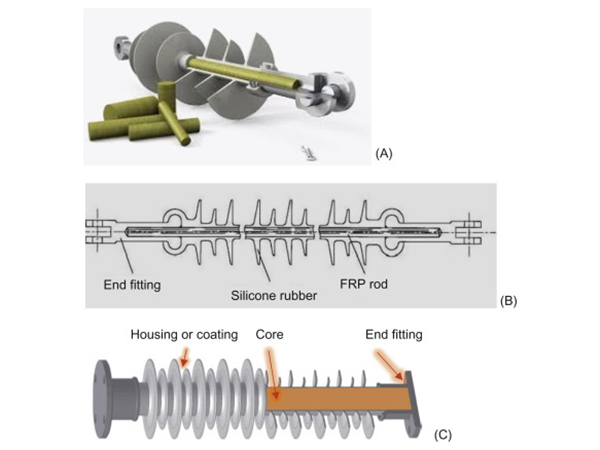

Component Breakdown of a Polymer Insulator

- +86 18875849654

- [email protected]

- No. 1965, Liubai Road, Liushi Town, Wenzhou City, Zhejiang Province, China