What Are Pin Insulators

Pin insulators are a popular insulator found in overhead power transmission and distribution lines, as well as communication cables. They hold the wires and offer insulation, therefore they are a crucial component in these systems. This article will offer a thorough introduction to pin insulators, including their construction, operating principle, materials, specialized uses, installation requirements, maintenance suggestions, and differences from other types of insulators. We will also discuss the benefits of our company’s pin insulators, providing you a thorough grasp of this critical technology.

Pin insulators are electrical insulators used in overhead power transmission and distribution lines. They support and insulate the wires on cross-arms, guaranteeing the safe and dependable transfer of electricity while preventing current from escaping into the cross-arm or pole, which might pose a safety risk. Pin insulators are often constructed of ceramics, glass, or composites. Their ends are pin-shaped, allowing them to be directly attached to the cross-arms on poles.

Pin Insulator

Structure Of Pin Insulators

Pin insulators have a very basic construction, consisting of the following parts:

Insulator: Typically constructed of ceramic or glass, this component combines mechanical robustness with high insulating performance.

Metal Pin: This component is meant to quickly attach the insulator to the cross-arm and provide support.

Shed (Skirt): By combining many insulating units or skirts, this design improves the electrical performance of the pin insulator. It also helps rainfall drain rapidly, avoiding dust and filth accumulation and lowering the danger of contamination.

Fastening Devices: Such as bolts and nuts are used to secure the insulator to the cross-arm.

Working Principle Of Pin Insulators

Pin insulators are made with several skirts to increase surface area and creepage length. This design not only eliminates electrical mishaps in adverse weather circumstances, but it also prevents the accumulation of dust and rainfall, lowering the danger of safety concerns. Their working philosophy is centered on delivering superior insulation. When electricity travels through the wires above the cross-arm, the pin insulator’s high-resistance insulating material stops it from reaching the cross-arm, successfully averting mishaps. Furthermore, their strength offers a sturdy foundation for the wires. Pin insulators have a basic form yet provide substantial protection, ensuring the safe transfer of energy.

Material Of Pin Insulators

Pin insulators are often built of materials that provide great insulation and mechanical strength. Common materials include:

Ceramic is the most often used material for insulators. It has strong electrical insulation, weather resistance, and mechanical strength, hence it is frequently utilized in insulator manufacture.

Glass has stronger mechanical strength than ceramic, weighs less for the same size, and is transparent, making examination easier. This makes glass a popular option as well.

Composite materials are polymer-based materials reinforced with fibers, such as silicone rubber or epoxy resin. These materials are more resistant to pollutants and aging, as well as lighter than ceramic or glass.

Application Of Pin Insulators

Overhead transmission and distribution lines: Used in medium, low, and high voltage power lines.

Power substations: Applied to isolate and support equipment within the substation.

Industrial and commercial buildings: Used for internal power distribution systems.

Installation Requirements For Pin Insulators

1.Before installation, verify the insulator to ensure that it is free of defects and that the model and specifications meet the required standards.

2.Clean the insulator’s surface of any dust, debris, or paint residue.

3.When attaching the pin insulator to the pole and wire clamp, make sure there is no compression at the connection locations.

4.Install spring pins, screws, and nails for strain wire strings from the top down.

5.Spring pins, screws, and nails for suspension wire strings should be inserted toward the power-receiving side, with incoming wires entered from inside to outside on both sides and the center wire inserted from left to right.

6.The distance between the insulator skirt and the live components should be more than 50mm.

7.After the suspension clamp is installed, the insulator string should be perpendicular to the ground plane. In special cases, the inclination angle along the line direction should be less than 5°, and the offset value should be less than 200mm.

8.When installing porcelain cross arm insulators, the top skew along the line should be less than 10mm, the top should be tilted upwards by 5° to 15°, and the skew should be less than 20mm.

9.The flat surface of the fixed iron bolt head of the pin insulator should be close to the component, and the porcelain head should not be skewed after tightening.

10.The threading directions of various hardware bolts, nails and spring pins on insulator strings, conductors and lightning protection lines should be consistent.

Maintenance And Care Of Pin Insulators

For the maintenance and care of pin insulators, the following should be regularly checked:

Cracks or damage: If any cracks or damage are found in the insulating material, the damaged insulator should be replaced immediately.

Contamination: Clean any pollutants from the surface of the insulator promptly to maintain its optimal insulation performance.

Fasteners: Regularly check all fasteners to ensure that all bolts and nuts on the pin insulator are secure and not loose.

Distinctions Between Pin Insulators And Other Insulators

Pin insulators have a simpler structure than other types of insulators, making them easier to produce. Pin insulators are normally fastened to the cross-arm with bolts or nuts, although other types of insulators may require a different installation method. Pin insulators are often utilized at lower voltage levels and are less expensive than other types of insulators.

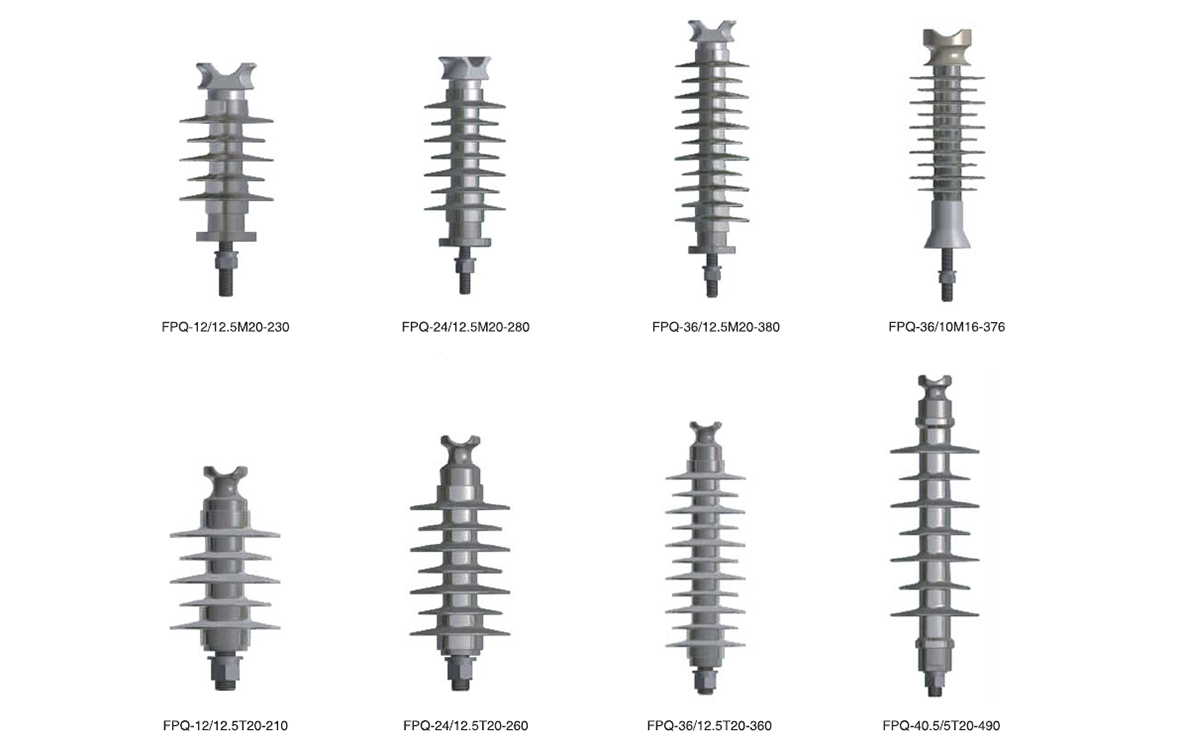

SUNJ's Pin Insulators

SUNJ is a well-known power accessory firm founded in 2009 that specializes in overhead line accessories, namely polymer insulators. The firm manufactures a variety of power accessories, including pin insulators, using an ISO9001-certified quality management system and an ISO14001-certified environmental management system. SUNJ’s pin insulators provide the following features:

Material: Made from ceramic, glass, or composite polymers.

Rated voltage: Typically between 11 kV and 66 kV, or higher.

Mechanical load capacity: Varies by design, generally up to 10 kN or more.

Operating temperature: From -40°C to +60°C.

Creepage distance: Depending on the model, ranging from approximately 440 mm to 920 mm.

Conclusion

Pin insulators, as key components in power systems, have strong construction, great insulation performance, and are simple to install, making them an excellent choice for critical infrastructure projects such as overhead power and communications lines. Power system designers and maintenance workers must understand pin insulators’ structure, operating principle, materials, applications, installation requirements, and maintenance.