Aluminum Lugs

1 Lightweight: The density of aluminum is low, which makes the weight of aluminum terminal blocks relatively light and easy to install and operate.

2 Low cost: Aluminum is a common metal with a relatively low price, so the cost of aluminum terminal blocks is also low.

3 Good conductivity: Although aluminum is not as conductive as copper, it can still meet the requirements of many electrical connections.

4 Good corrosion resistance: After proper surface treatment, such as anodizing or coating, aluminum terminal blocks can have good corrosion resistance.

5 Good machinability: Aluminum has good machinability and can be easily bent, cut and formed to meet different connection needs.

6 Overseas Warehouse in Turkey: Fast Delivery, Lower Shipping Costs and Localized Service

Main Products

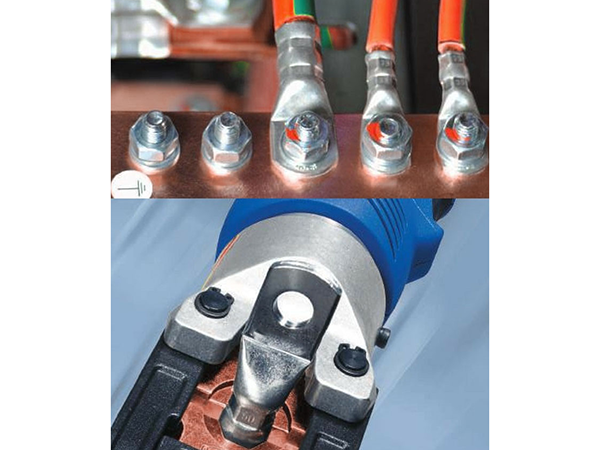

DL Aluminium Crimp Lugs

DL lug is an important component used on power transmission lines. It ...

AU Aluminium Crimp Lug To Din

AU lug is an important component used on power transmission lines. It ...

GL Aluminum Tube Cable Connector

GL pipe connector is an important component used on power transmission...

GLB Aluminum Tube Cable Connector

Aluminum connector GLB lug is an important component used on power tra...

Learn About Aluminum Terminal Blocks

Aluminum terminal blocks are metal products used for electrical connections, mainly used to connect aluminum wires or other metal conductors.

It is usually made of pure aluminum or aluminum alloy and has the following characteristics:

● Conductivity: Aluminum is a good conductive material. Although its conductivity is slightly inferior to copper, it can still meet the needs of most electrical connections.

● Light weight: Aluminum has a lower density, so aluminum terminal blocks are relatively light and easy to install and operate.

● Corrosion resistance: Through surface treatment, such as anodizing or coating with preservatives, aluminum terminal blocks can improve their corrosion resistance and adapt to different environmental conditions.

● Lower cost: Compared with copper terminal blocks, aluminum terminal blocks have a lower cost, which is attractive for some cost-sensitive projects.

● Machinability: Aluminum has good machinability and can be bent, cut and formed as needed.

What Are The Characteristics Of Aluminum Lugs?

● Conductivity: Although aluminum is not as conductive as copper, it can still meet the requirements of many electrical connections.

● Lightweight: The lower density of aluminum makes aluminum terminals relatively light and easy to install and operate.

● Corrosion resistance: After proper surface treatment, such as anodizing or coating, aluminum terminals can have good corrosion resistance.

● Cost-effectiveness: Compared with copper terminals, aluminum terminals are generally more economical.

● Machinability: Aluminum has good machinability and can be easily bent, cut and formed to suit different connection requirements.

● Coefficient of thermal expansion: Aluminum has a large coefficient of thermal expansion, which may have a certain impact on the connection in high temperature environments and needs to be considered in the design.

● Strength: Aluminum has relatively low strength and may require additional support or fixing in some applications.

Over 18 Years Direct Factory

80+

Countries served

32+

Utility Approvals

800+

Projects Executed Globally

SUNJ Products More Information

SUNJ Electric is a power transmission and distribution enterprise with R&D, manufacturing, trading and services. With excellent quality, design and manufacture and competitive prices, SUNJ products are top sellers in China and have exported to Asia, Europe, America, Middle-East and Africa and numberous other regions. We warmly welcome all over the world friends cooperate with us. Together to contribute a better and stronger power system.

Precautions For Use Of Aluminum Lugs

When using aluminum terminal blocks, you need to pay attention to the following points:

1.Choose the appropriate specifications and models to ensure that they match the wires and electrical equipment.

2.Install correctly to ensure a firm connection and avoid looseness and poor contact.

3.Inspect and maintain regularly to detect and deal with possible problems in a timely manner.

4.Pay attention to safety and avoid operating under power.

- +86 18875849654

- [email protected]

- No. 1965, Liubai Road, Liushi Town, Wenzhou City, Zhejiang Province, China