About SUNJ Products

Power fittings are an indispensable part of the power system and are of great significance to ensure the normal operation of the power system.

Structural performance and usage specifications of each product so that it can be correctly applied to power construction

Maintain regular maintenance and inspection

The design and manufacturing of power fittings need to meet strict standards and requirements to ensure their quality and reliability. At the same time, during use, regular maintenance and inspection are also required to ensure its normal operation and extend its service life.

PG Clamp for ACSR line Advantages:

1) Advanced forging technology enhances the mechanical strength of the clamp.

2) Special designed screw hole and arc shape of the body allow clamp to adjusts to different cable size on each side.

3) Clamp body is made of aluminium with excellent electrical conductivity.

4) Gross-grooved clamp channels enhance both mechanical pullout strength and electrical conductivity.

5) Materials of bolt and nut are optional depend on customer request. Options including Hot-dip galvanized steel and Stainless steel

6) Pressure pad is applied to achieve uniform pressure along the clamp.

The installation method operation steps are as follows:

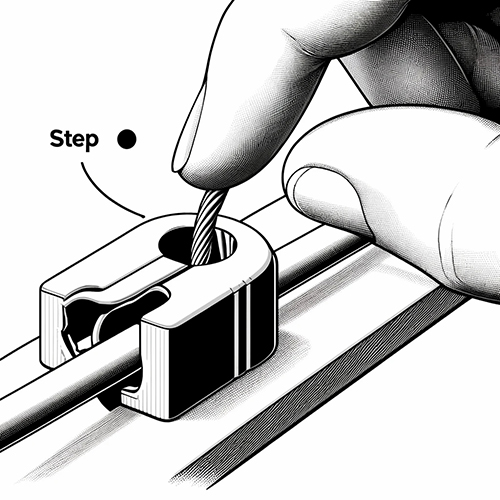

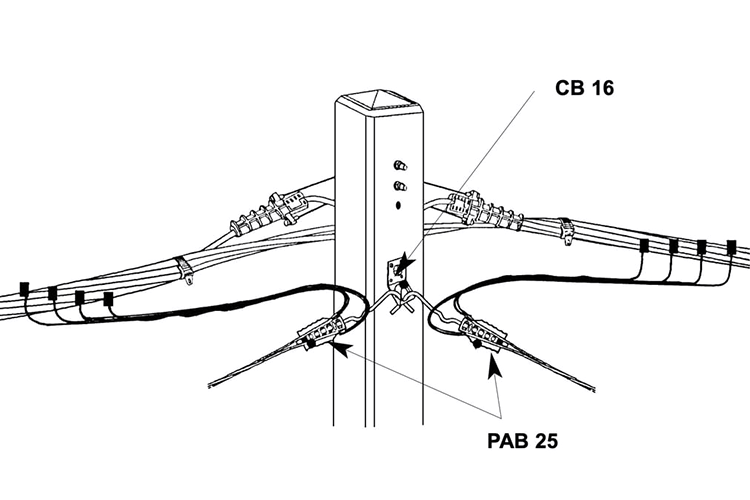

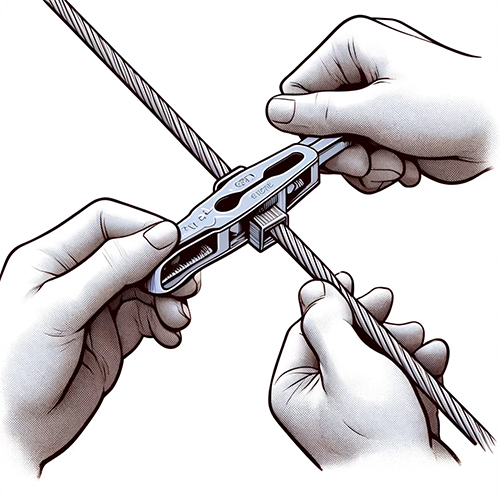

Threading the Wire

Pass the wire through the hole inside the cable clamp, making sure the size of the hole matches the diameter of the wire.

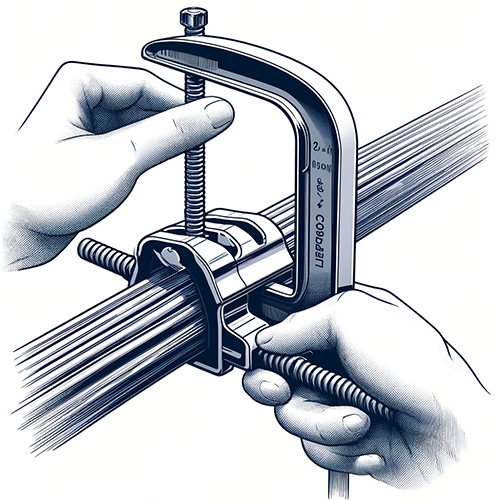

Aligning the Wires

Place a wire above and below the parallel groove clamp, and tighten the wires to keep them on the same level.

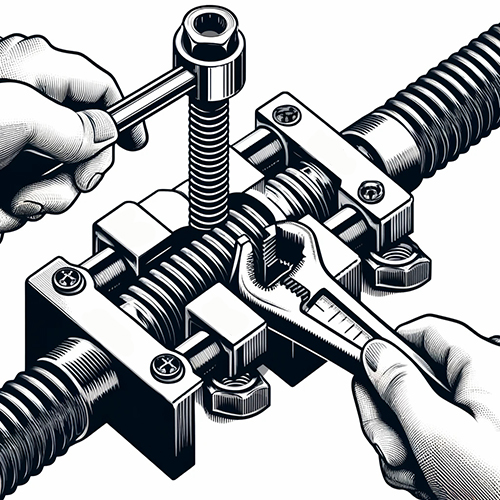

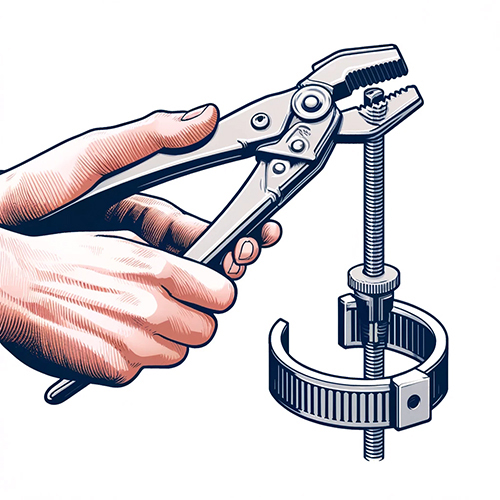

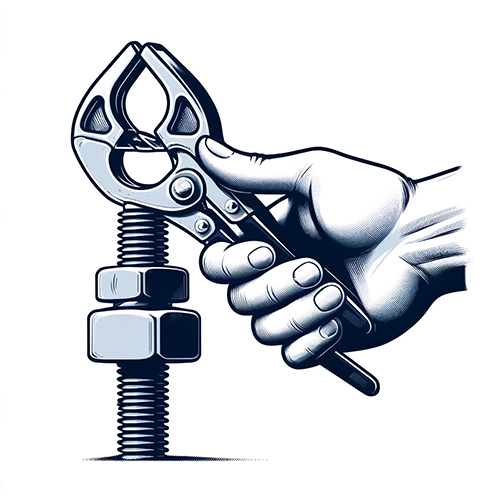

Securing the Clamp

Use a wrench or wrench torque wrench to tighten the parallel groove clamp bolts to ensure that the bolts, nuts and spring clamps are all fixed.

DTL-2 Bimetallic Cable Lug Advantages:

1) Alternative sizes can be made to order for approved order quantities.

2) Barrels are capped and filled with grease so as to avoid oxidation of the aluminum.

3) The technology of friction welding is wonderfully adopted. Cable lugs are fully annealed to guarantee optimum ductility.

4) Distinguishing features of strong weld intensity, good nature in electrification resistant galvanic corrosion and long service life.

The installation method operation steps are as follows:

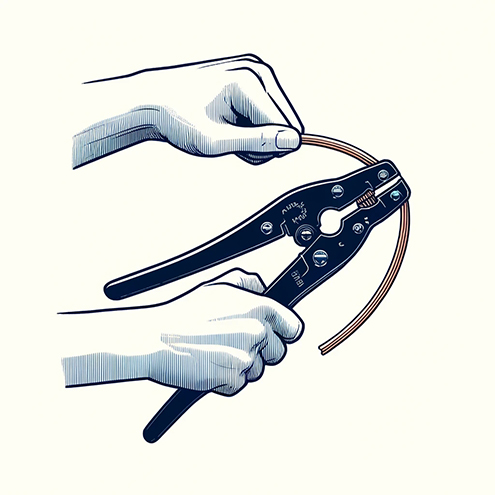

Wire Stripping

Peel off the two copper wires and aluminum wires respectively to expose the inner core;

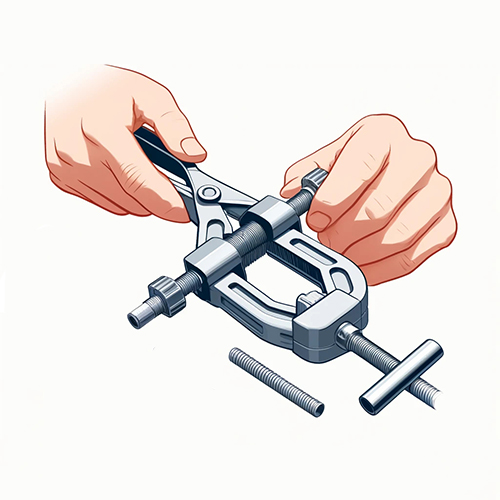

Wire Insertion Align

Insert the copper wire and aluminum wire into the crimper respectively, making sure to align them correctly;

Crimp

Hold the handle of the crimper with your hand, apply pressure, and press the aluminum wire and copper wire together tightly;

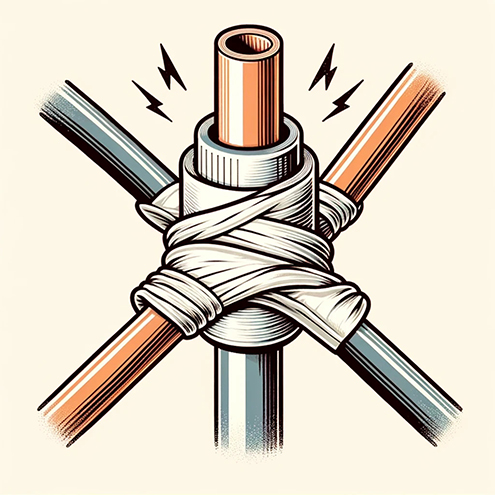

Insulation Treatment

Wrap the connector with insulating tape or pipe sleeves to ensure no leakage.

Tension anchoring clamp for overhead line Advantage:

1) The body of the clamp is made of special polymer material, no change when exposure to ultraviolet light. The body materials are UV-resistant.

2) It can fix the wire firmly and doesn't affect the insulation.

3) No tools required.

The installation method operation steps are as follows:

Open the Tension Clamp

Take out the tension clamp and unfold its structure.

Set on the End of the Line

Put the tension wire clamp on one end of the line.

Clamp the Wire

Use pliers to clamp the wire into the inside of the tension clamp, making sure the wire is clamped correctly.

Secure the Upper End

Use the appropriate tool (such as a winch or wrench) to tighten the upper end cable and make sure it is firmly fixed.

Check the Clamping

Finally check the clamping to make sure it is neither too loose nor too tight.

Complete the Installation

After the installation is complete, check that all parts are working properly and perform necessary tests to verify the quality of the connections.

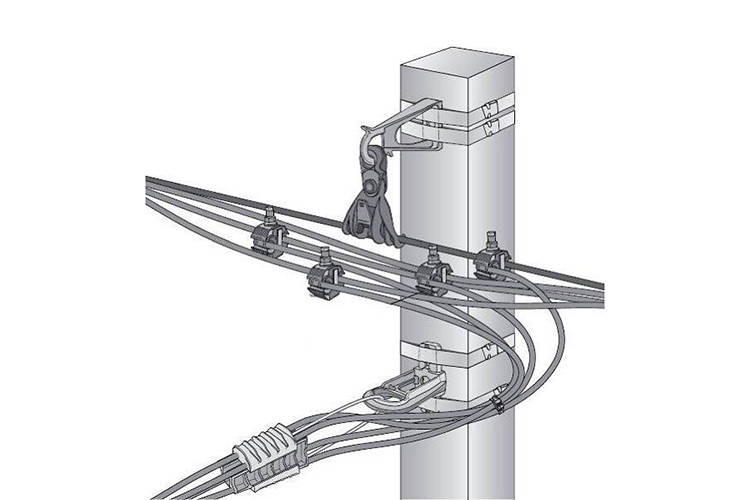

ABC Cable Suspension Clamp Advantage:

1) Cutting section is universal, and insulated line is fixed by nut. The part connecting the wire is made of dielectric material.

2) Hanging the self-supporting insulated wire on the bracket with maximum angle of 90 degrees.

The installation method operation steps are as follows:

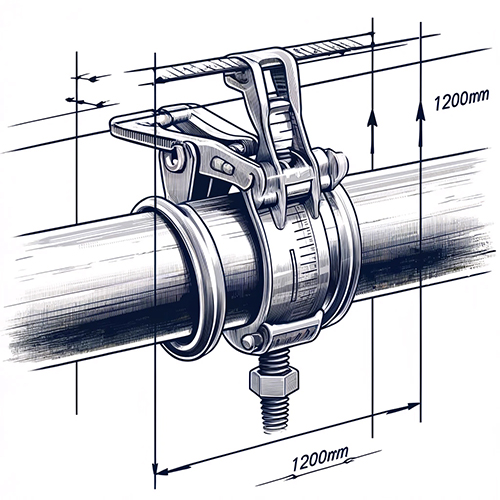

Determine the installation location

First, determine the location of the suspension clamp to be installed on the steel pipe or wire according to the needs of the power line. Normally, the installation location should be more than 1200mm from the ground.

Install the bolts

After determining the installation location, we need to drill holes in the wires or steel pipes, insert the bolts into the holes, and fix the nuts and washers at the other end.

Fix the suspension cable clamp

Slowly place the suspension cable clamp onto the bolt, and then use pliers to secure it.

Check the fixation

After confirming that the suspension clamp is firmly fixed, not loose, and does not tilt in any way, the installation operation can be completed.

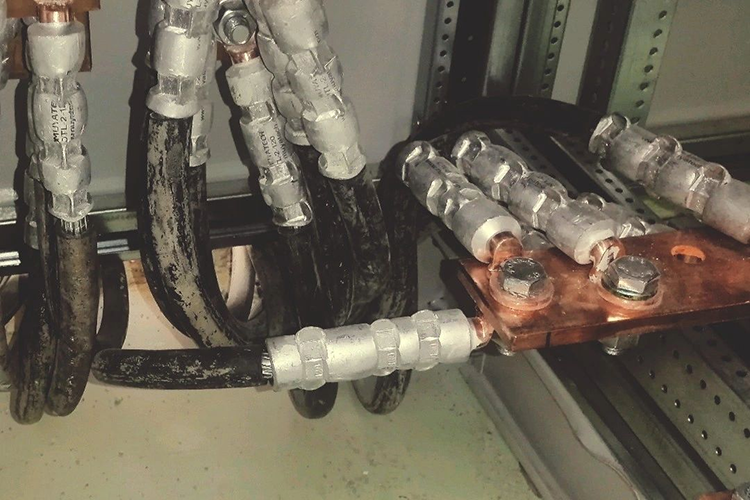

Waterproof insulation piercing connectors test voltage 6 kV in water Advantage:

1) (IPC) SERIES INSULATION PIERCING CONNECTOR had passed 6KV test under water for 1 Min.

2) Designed for all weather applications and easy to install.

3) Its self-seam frame is wet proof, water proof, and anti-corrosive, which can prolong the using life of insulated lead and connector.

The installation method operation steps are as follows:

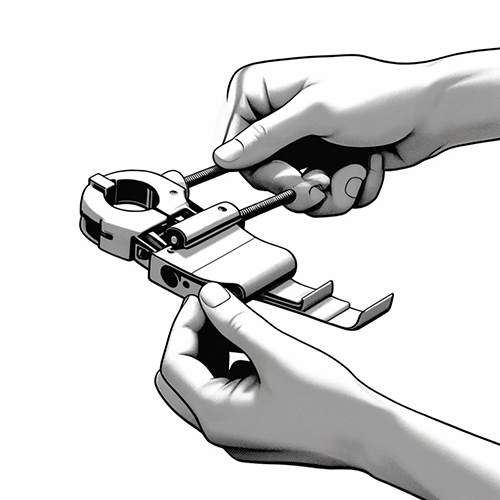

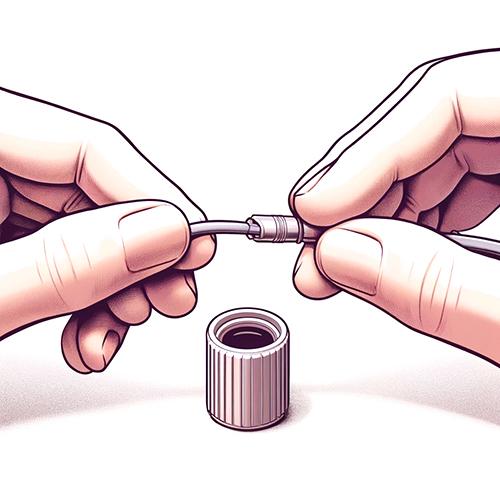

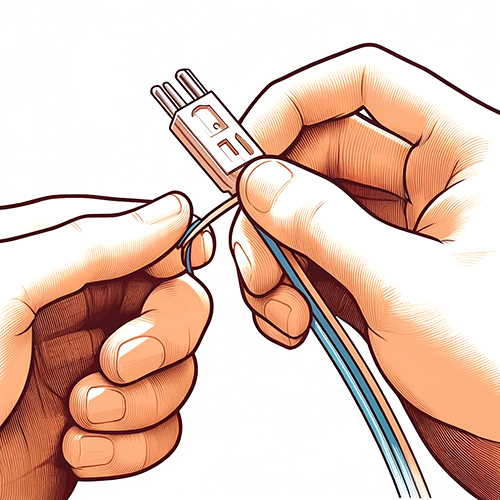

Adjust the Connector Nut

Adjust the connector nut to suitable location.

Insert the Branch Wire

Put the branch wire into the cap sheath fully.

Insert the Main Wire

If there are two lays of insulated lay in the main cable, should strip a certain length of the first insulated lay from inserted end.

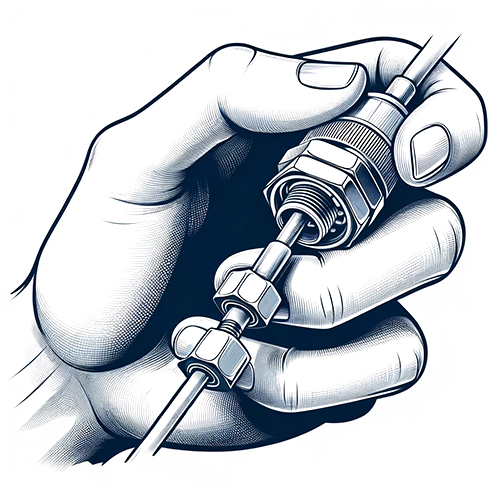

Hand Tighten the Nut

Turn the nut by hand, and fix the connector in suitable location.

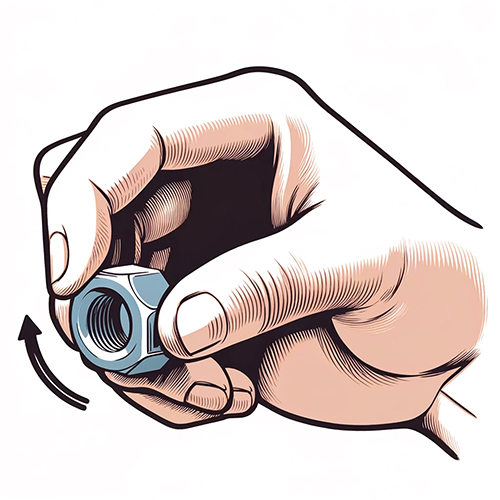

Tighten with a Sleeve Spanner

Screw the nut with the sleeve span

Screw the nut with the sleeve spanner

Continue screwing the nut until the top part is cracked and drops down.